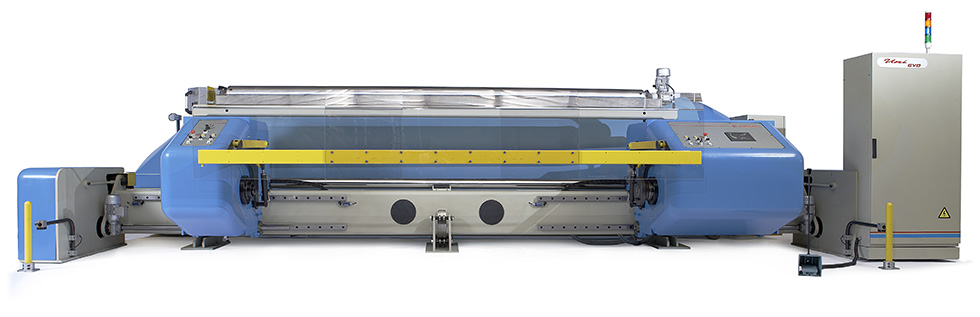

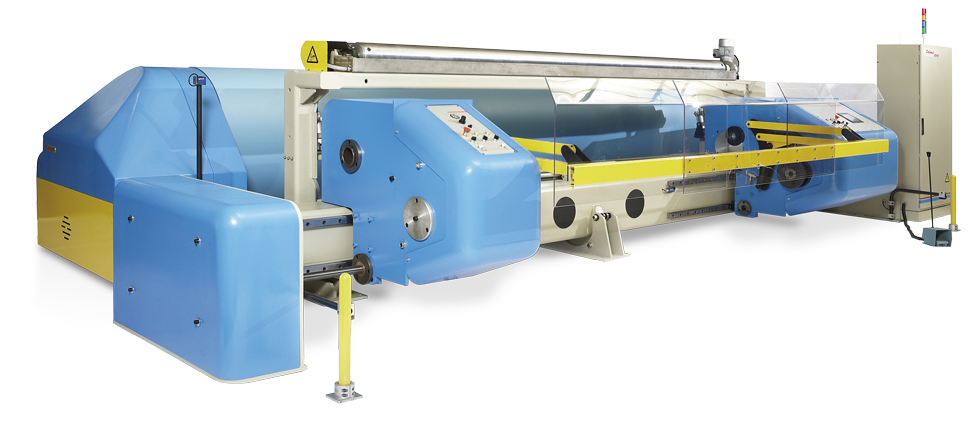

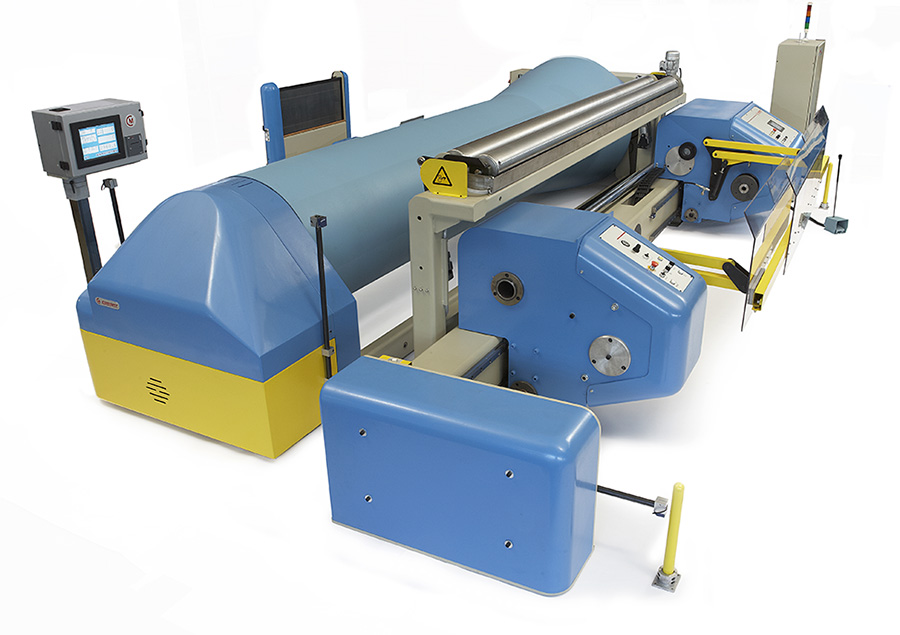

COMSAT’s extensive experience in the field of weaving preparation, has allowed the creation of sectional warper UNI EVO.

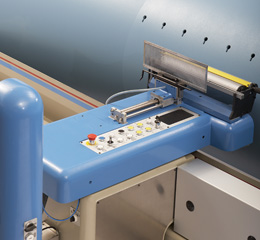

Evolution is the starting point of the new UNI EVO. It presents a series of innovations, getting a top quality warp and high productivity with the goal of always offering the best performance.

The versatility of the new EVO UNI warper introduced by COMSAT, can successfully meet any type of application.