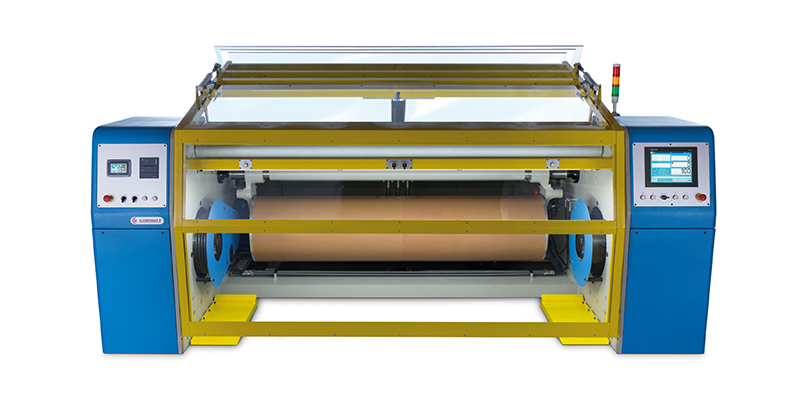

COMSAT, in stirving to remain at the forefront of technological progress, has developed the advanced and fully computerized UNI series sectional warping machine.

This new generation of warpers confirms the “Design and Technology” motto that has set COMSAT aside throughout their 55 years of history. The UNI series allows warping of any type of material, from cut fibers to continuous fibers with or without twist, as well as glass, plastic, etc… thanks to its experiences and highly evolved, fully automatic advance determination system, eliminating the need for previous calculation or for entering parameters on the nature of the yarn.