COMSAT has four different types of warp guard depending on the types of threads to be processed. The COMSAT IR model is based on a photoelectric stop system for the detection of wire breaks. The Eltex-UNI, Eltex-Unimag and Eltex EyETM systems are systems developed by the manufacturer Eltex of Sweden in conjunction with COMSAT to achieve a very precise detection in a fully automatic way of the threads that run through the creel.

COMSAT IR

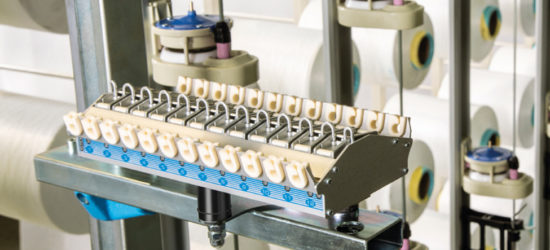

An electronically controlled warp stop motion system equipped with “light on signal” due to yarn breakage and individual blocking device for each stop.

ELTEX-UNI

Piezoelectric warp stop motion system sensitive to yarn friction, immediately stopping the warping unit when it fails to detect friction in any of the yarns. In this way, it ensures that the breakage is detected even though the yarn might be connected to the reed. The broken yarns can be detected fast, as the indicators are installed on the side of the creel, section and eyelet of the warp stop motion.

ELTEX-UNIMAG

Piezoelectric warp stop motion system sensitive to yarn friction, installed on the outlet of each tensioner. The broken yarns can be detected fast, as the indicators are installed on the side of the creel and the tensioner.