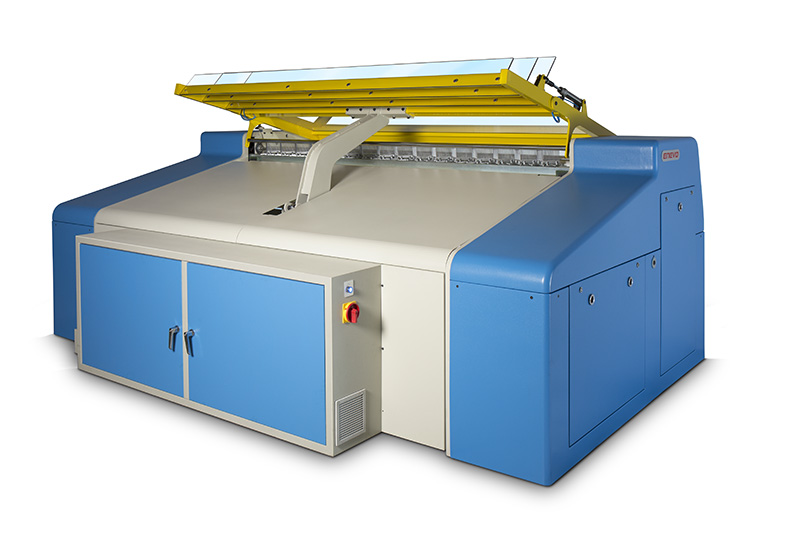

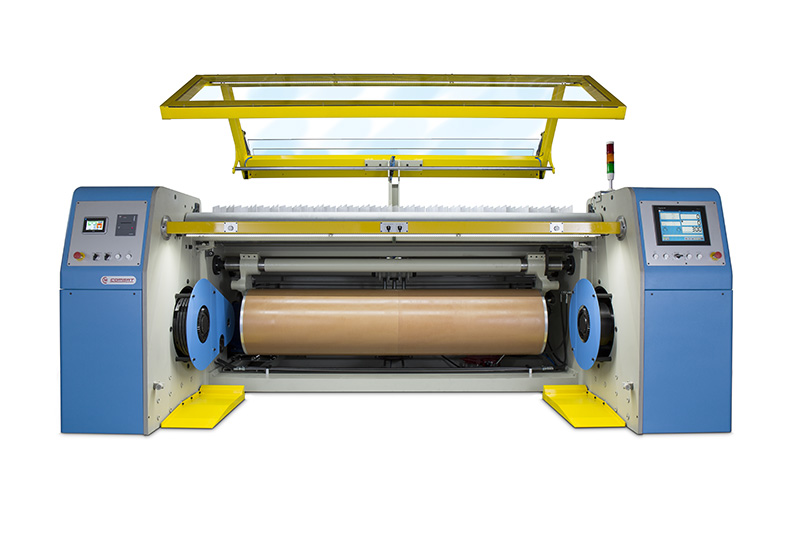

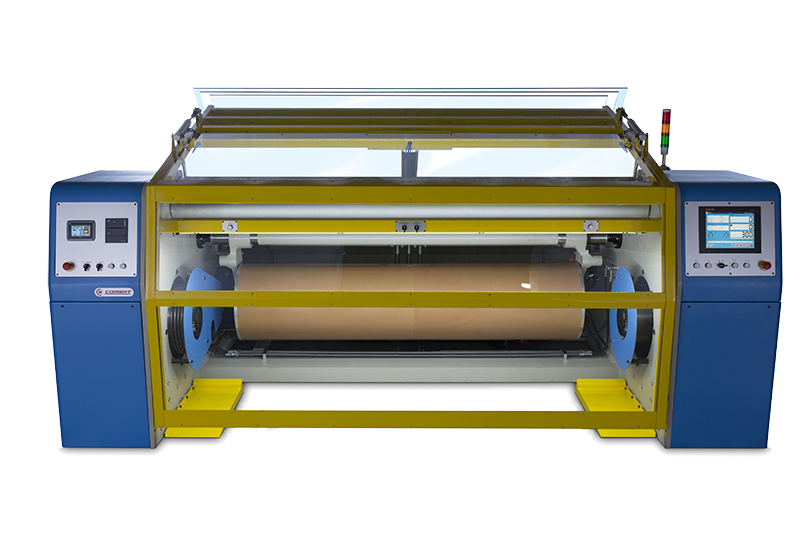

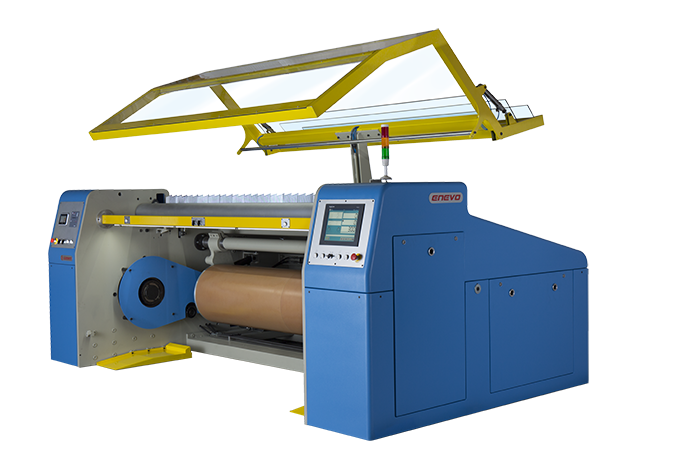

DIRECT WARPER ENEVO

COMSAT’s extensive experience in the field of weaving preparation, has allowed the creation of direct warper ENEVO.

Ease of use, versatility and high quality are the starting points of the new direct warper ENEVO. It presents a series of innovations, obtaining a maximum warp quality and high efficiency with the goal of always offering the maximum performance.

Minimum loss of yarns

Minimum loss of yarns